.png) |

TPV Granules

|

| Designed to perform in different range of temperatures and extreme weather conditions, Miroad TPV granule is the top-grade choice for pour-in-place rubber safety surfaces. |

| |

| Using premium grade polymer as a base element in the compound structure, the manufacturing of Miroad TPV combines both peroxide- and thermoplastic-vulcanizing technology. This enhanced curing process allows Miroad TPV to achieve an even more stable formation of cross-links between long rubber molecules and result in improved aging properties. |

|

|

| |

|

| Product Features & Benefits |

| |

|

|

| |

| Peroxide and Thermoplastic Curing to Achieve Exceptional Aging Properties |

|

|

|

|

| |

| Superior Chemical and Abrasion Resistance for Longer Life Span |

|

|

|

|

| |

| Highly Advanced Granulating Technology for Various Granule Sizes |

|

|

| |

|

|

| |

| Standard-Compliant Hardness for Superlative Impact Absorption |

|

|

|

|

| |

| Improved Color Stability and Color Permenance |

|

|

|

|

| |

| Enhanced Resistance to Extreme Weather and Ultraviolet Light |

|

|

|

|

| |

| Additional Especial Benefits |

| |

| The utilization of peroxide- and thermoplastic-curing technology enables Miroad TPV to achieve comparatively excellent physical and chemical properties than EPDM Granules or other TPV Granules in the market, these advantages include: |

| |

- High Versatility, Flexibility, Elasticity and Durability : Better Flooring Performance

- Resistance to Chemical, Impact, Abrasion : Low Maintenance and Long Life Span

- Consistent Size Distribution and Color : Facilitate Smoother Installation Process Better Rubber-Binder

- Compatibility : Consume up to 30% Less PU Binder

|

|

| |

|

|

|

|

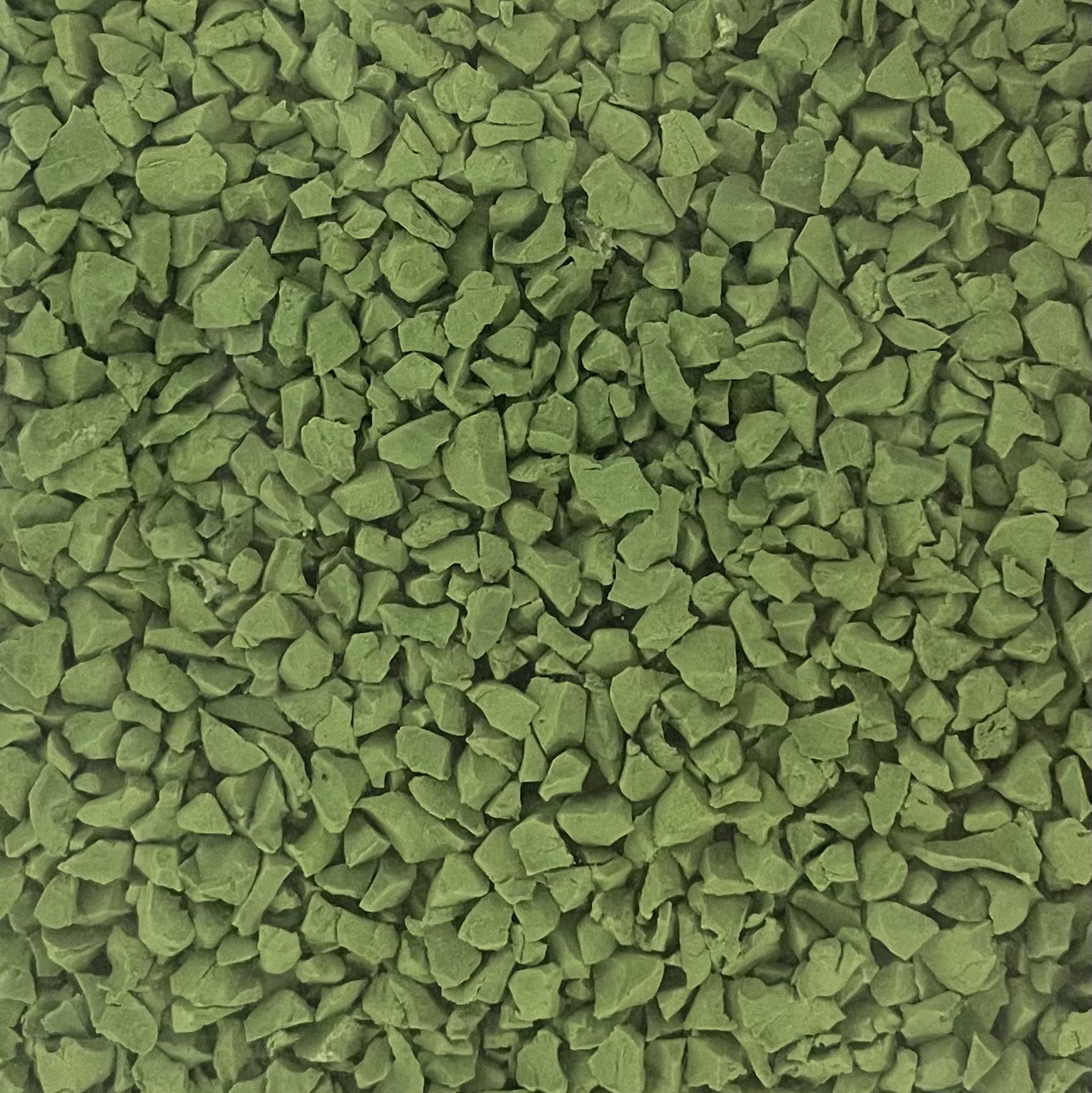

| Color |

| Light Green |

| |

| Code |

| T03 |

|

|

|

| Color |

| Light Blue |

| |

| Code |

| T05 |

|

|

|

|

|

| Color |

| Golden Yellow |

| |

| Code |

| T08 |

|

|

|

| Color |

| Light Brown |

| |

| Code |

| T10 |

|

|

|

| Color |

| Light Grey |

| |

| Code |

| T12 |

|

|

|

|

|

|

|

|

|

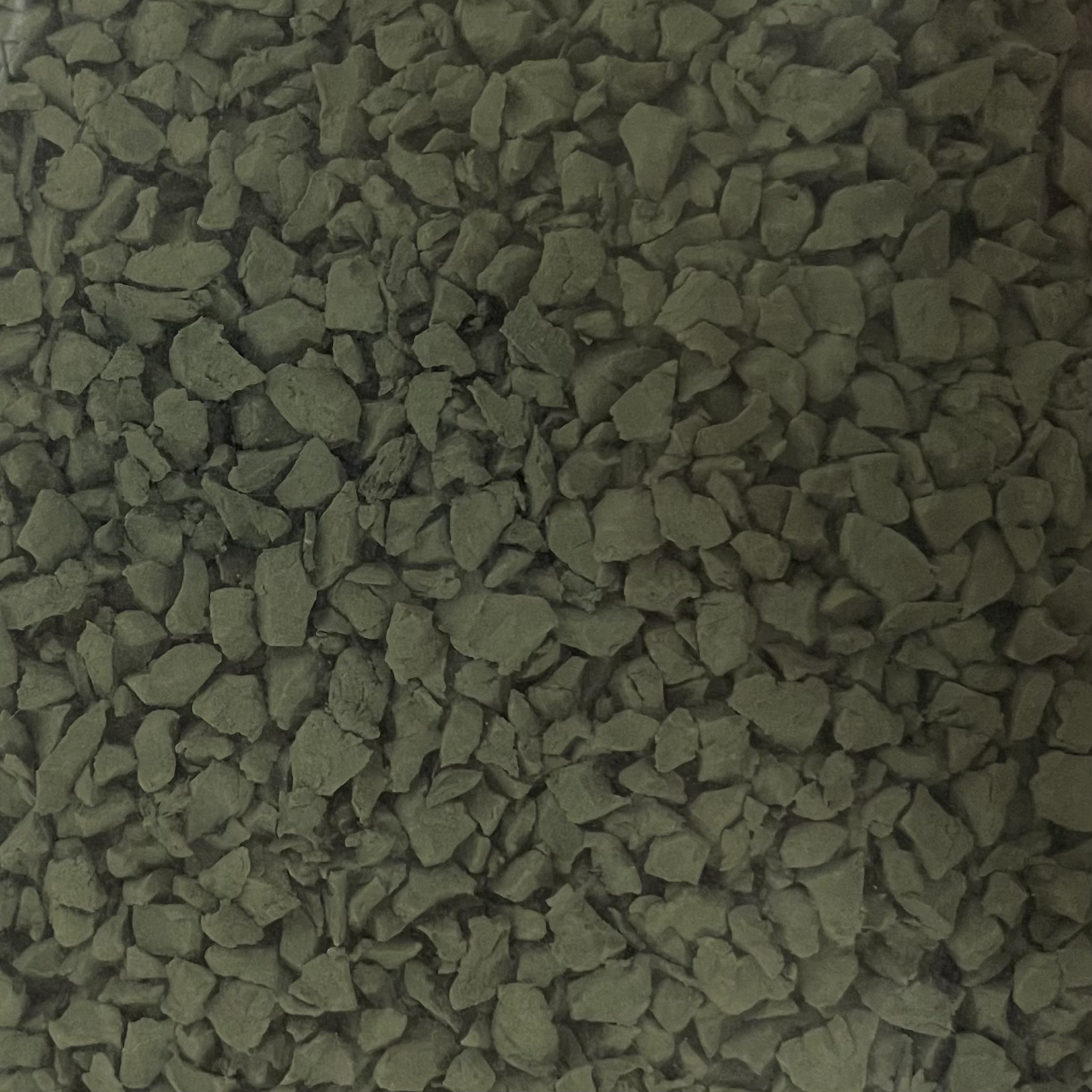

| Color |

| Grass Green |

| |

| Code |

| T17 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |